Daily maintenance of palletizing robot

Date:2019-08-09 Views:978

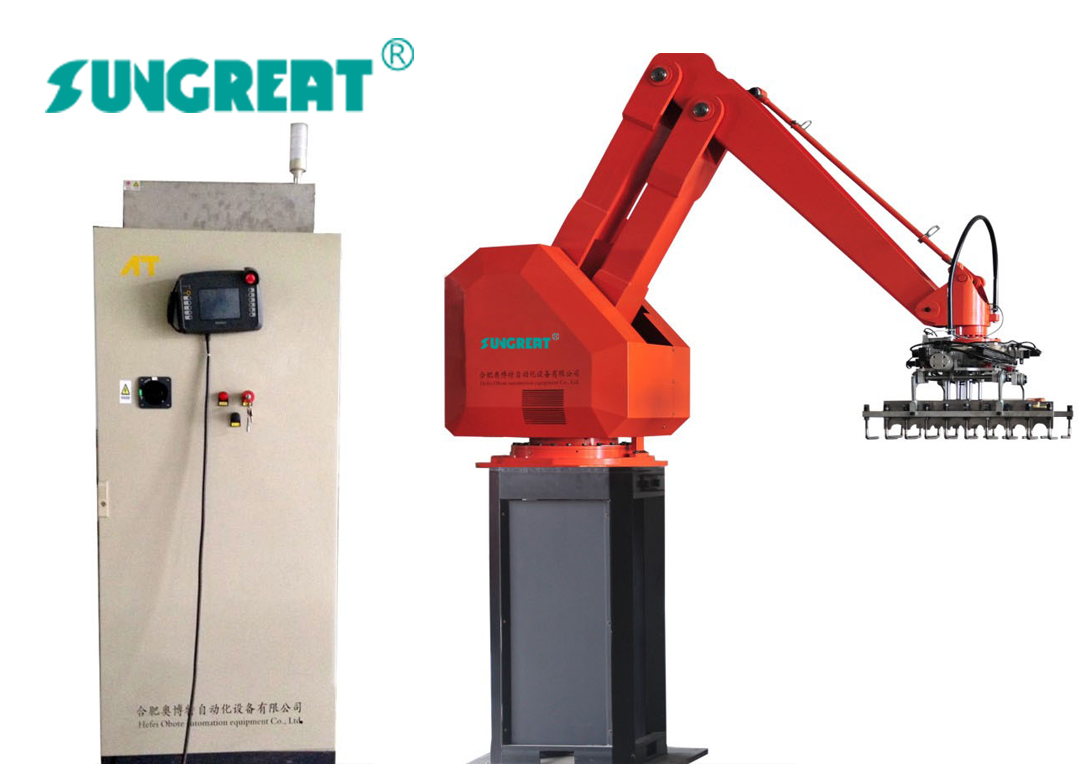

Storage automation equipment generally needs regular maintenance, and palletizing robots are no exception. Adhering to regular maintenance is conducive to extending the service life of the equipment and keeping it in good working condition.

The palletizing robot is a precision automation equipment, and the mechanical components and control system used need regular maintenance.

The main moving parts and transmission parts of the palletizing robot should be regularly checked for wear and lubricated, and the heavily worn parts with potential safety hazards should be replaced in time. Lubricate the transmission system through the "send lubricating oil" key on the operation interface.

Maintenance of control system

The control system of the palletizing robot needs to be regularly inspected and maintained to check whether the power lines and signal lines have coking or damage, and replace the damaged lines in time to prevent short circuit and electric shock accidents. Check whether the connectors are loose, and tighten the loose connections in time to ensure the normal operation of the robot.

The specific daily maintenance and service steps are as follows:

1. Keep the surface of the stacking robot clean and clean the dust in time;

2. Check whether the fixing bolts of the stacking robot are loose once a week;

3. Lubricate the cylinder support shaft, hinge seat hole and shaft every day. Fill 1-2 drops of lubricating oil each time;

4. Check whether the gripping teeth are loose and whether the surface has cracks every day;

5. Check whether the connections of air pipe fittings, regulating valves and tees are firm every day;

6. Check whether the grab action is normal and whether the solenoid valve works normally every day.