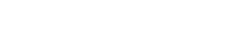

1. Pour the material ready for color selection into the vibrating feeding bucket, and the material will fall into the material distribution tank after high-frequency shaking of the feeder.

2. each material will fall into the sorting box through the channel. Each plate has 64 channels, and each channel corresponds to an air valve, so as to ensure the cleaning rate of each material.

3. when the materials fall into the sorting box, the front and rear two high-definition color cameras will take high-frequency comprehensive photos of each material, without missing a dead corner, and the photography speed is up to 3000 times /min.

4. all the pictures taken will be compared with the qualified materials through spectral analysis. If it is found that the materials are inconsistent with the qualified products and have different colors, the air valve will blow the unqualified materials out and fall into the overflow port, and the qualified materials will fall into the qualified port along the set route.

5. after sorting once, if it is found that the materials in the overflow port contain a small amount of qualified materials, the materials can be re introduced into the sub hopper and sorted again to achieve the best effect.

Obo special separator is applicable to the separation of the following materials

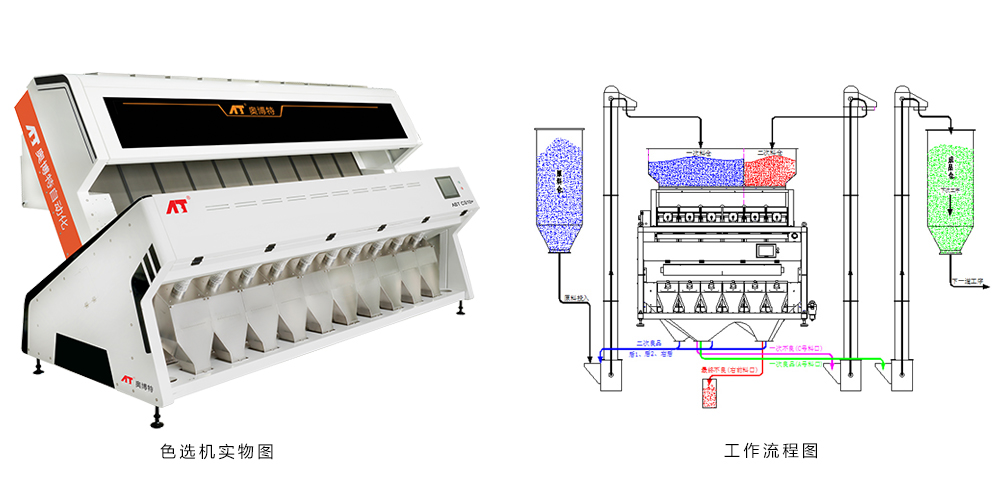

rice

Coarse Cereals

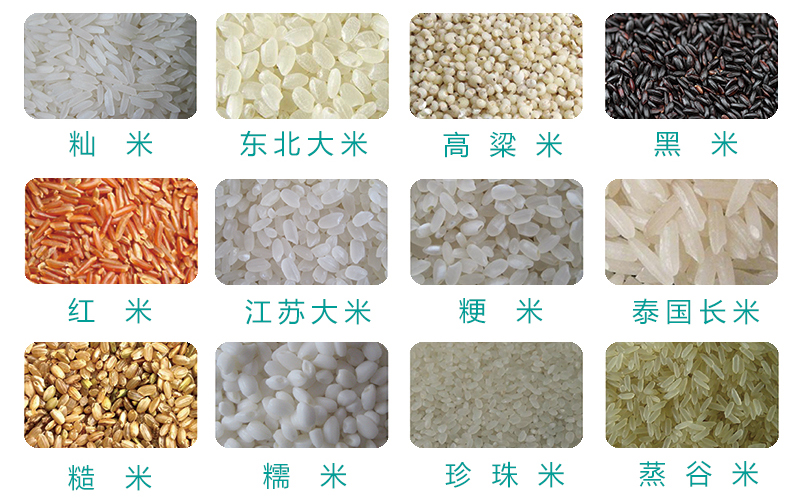

peas and beans

Fried nuts

Medlar / tea / dehydrated vegetables / industrial plastics