Brand: ejit

Color selection materials: all kinds of dehydrated vegetables

Output: 0.5~15 tons

Pre sales consultation: 151-5517-2666

After sales consultation: 400-181-0686

Product description

Product description

Ejet CSL crawler color sorter

CSL is a newly developed color sorter, with integrated structural design, unique transmission system, belt anti deviation design, the latest ash cleaning device, as well as dry and wet selection, color and shape selection and other functions. It can be applied to the selection, optimization and intelligent selection of beans, nuts, grains, seeds, dehydrated vegetables, industrial plastics and other particles.

Super intelligent recognition technology

1. automatically identify material characteristics, match the optimal sorting scheme, and reasonably realize customers' expectations for sorting;

2. provide customers with the best and most economical sorting scheme;

3. further realize the operation, learning, decision-making and control of color selection self adaptation, one click start and intelligent sorting.

HD micron camera

1. Exclusive customized ultra clear CCD sensor technology, combined with high-definition low distortion industrial lens;

2. It can scan materials for more than 10000 times in one second, with the recognition accuracy of micron level, and can accurately identify small and fine lesions;

3. It can recognize 130 million colors and realize faster (speed), higher (precision) and better (bring out).

Top customized high frequency solenoid valve

1. less air consumption and longer service life;

2. the rejection rate is higher, and it is no longer a vulnerable part.

Real time big data system

1. Realize remote operation, remote diagnosis, remote warranty and online training.

2. It can also collect and analyze the operation data of the equipment in real time, and push the remote business opportunity information, so as to ensure that customers can master all kinds of value-added business news at the first time.

Global original air duct circulating cooling system for color sorter

1. the unique heat dissipation system effectively improves the service life of LED and equipment.

2. enhance the stability of the circuit and make the reliability of the whole machine more superior to that of similar products in the market.

Stereoscopic cyclosuction

1. the three-dimensional annular suction system has the best ash removal effect and reduces the ash removal frequency.

2. Super long ash cleaning interval, easier production and better color separation effect.

Carefully designed according to the system dynamics to make the materials stably touch the light source intelligent dimming system

Advanced automatic dimming technology can automatically match the best brightness according to material sorting requirements and environmental changes, so as to achieve the best and most stable sorting performance.

Anti crushing discharge system

Reduce the rebound probability and greatly control the crushing and loss of materials.

Multispectral analysis technology

In combination with high-definition micron recognition technology and intelligent shape selection technology, non rice substances such as glass, plastic particles, desiccant and gravel can be accurately selected.

1

|

|

|

|

|

|

|

|

Sensor imported from Toshiba, Japan, with high line frequency scanning and high pixels to identify more minor disease spots and defects. |

|

Altera's latest generation of 1million logical units, with faster computing speed; FPGA has faster processing speed, larger output, stability and reliability. |

|

The combination of LED and precision optics provides high brightness and high uniformity lighting; Equipped with fast cooling fan.

|

|

With optical characteristics, it can deeply identify tiny defects and impurities, and realize high-definition scanning, identification and accurate elimination. |

|

|

|

|

|

|

|

|

Adopting the latest anodic oxidation treatment technology, the chute is smoother and more accurate; Ultra thick anodic oxide film is durable.

|

|

1000Hz high-frequency response, shorter tail gas, faster response speed, large output and low belt out; The service life is 10billion times.

|

|

The cutting-edge image processing system can recognize and automatically capture the image of materials, and analyze the good and bad characteristics of materials, so as to realize the real one click intelligence. |

|

Through feed structure, greatly improve the machine output; The straight through discharge hopper structure solves the problems of material blocking and stacking, reduces material collision and reduces material damage.

|

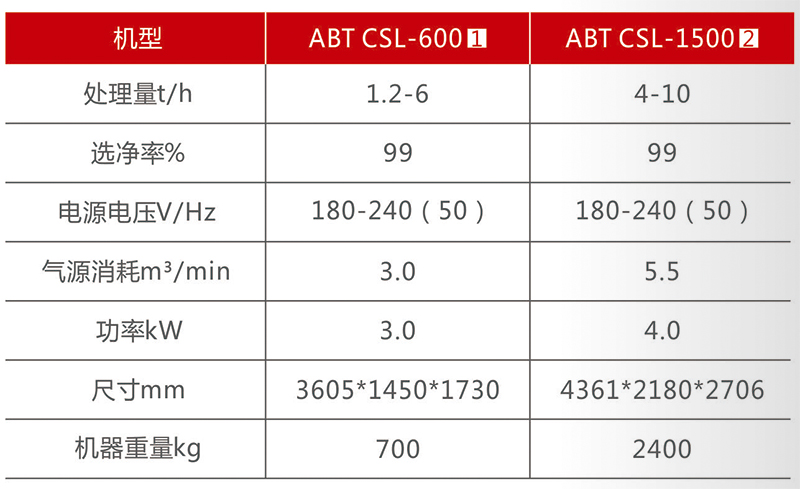

Product parameters

Product parameters

Color separation material

Color separation material

Mounting dimensions

Mounting dimensions

Customizable on demand