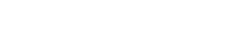

Product introduction:

Obert CS Series coarse cereals color sorter is a device that uses the photoelectric principle to detect and separate individuals (spherical, massive or granular) with abnormal color or infected with diseases and pests and foreign impurities from a large number of bulk products. The color separator is mainly used in the agricultural finishing industry. When the unqualified products and qualified products cannot be separated by screening equipment due to their very similar particle size, or the density is basically the same and cannot be separated by specific gravity separation equipment, the color separator can effectively separate according to the color difference of materials, and its unique role is very obvious.

Introduction to the workflow of the color sorter:

Color sorter is a process that uses CCD optical imaging technology to screen different color particles and impurities in color separation materials. After the materials arrive at the processing site, the proportion of different color particles and impurities (i.e. impurity content) shall be determined. The impurity content in the materials directly affects the color separation accuracy of the color separator. The higher the impurity content, the lower the color separation accuracy. Therefore, the operating mode and other relevant parameters of the color sorter are generally set according to the impurity content, output, type, etc. of materials before starting up. After the parameter setting is completed, the selected materials are loaded into the feed hopper of the color sorter through the lifting machine. At this time, the materials are fed from the feed hopper to the first selection chute channel (i.e. the color selection channel, whose surface should be flat and smooth without meter jumping). The material particles are arrayed in the chute channel for shaping and speed regulation to form a single layer, which slides out of the chute channel with uniform speed and falls into the CCD lens detection area. The main control system of the color sorter analyzes and discriminates the materials according to the data collected by the CCD lens, and blows out the defective products in the materials by using the high-speed air jet valve into the defective product bucket. The defective products sorted at the first time enter the secondary separation feed hopper for secondary color separation through a special elevator. High quality materials after secondary color separation will be sent to the next process for treatment; The defective products are judged as the final defective products, which will be stored and processed separately.

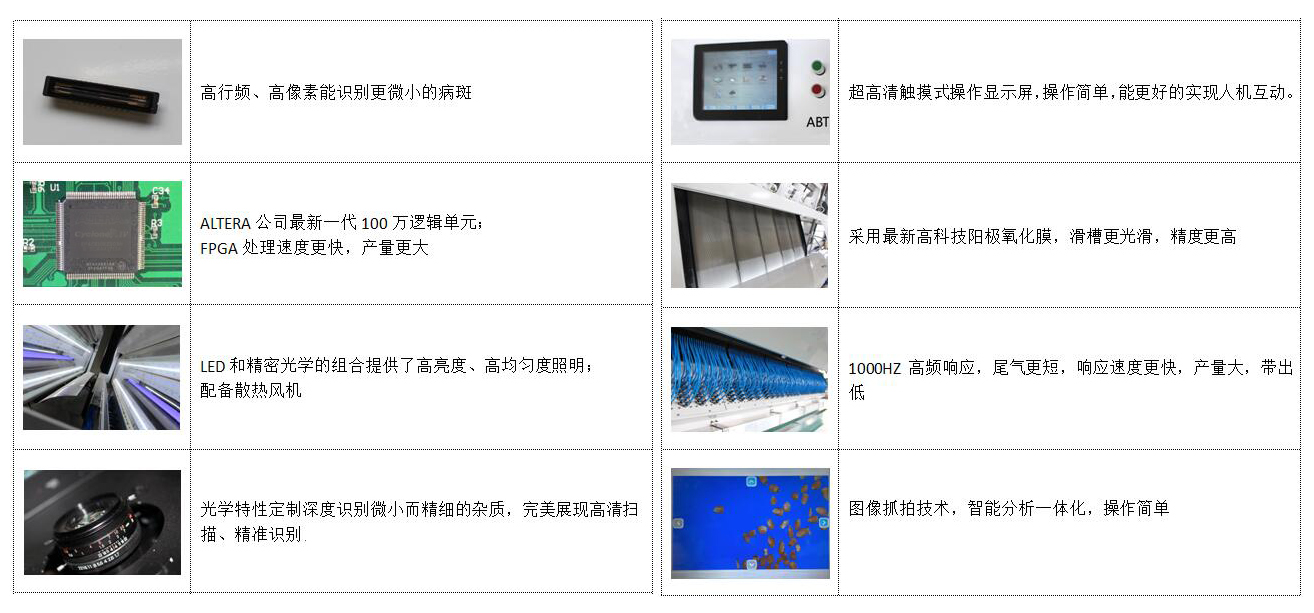

Product advantages:

More shapes and colors than you can imagine

Abt CS series color sorter is a universal color sorter newly developed by Obert automation. The whole machine has simple mechanism, stable color separation performance and simple operation. It is suitable for the selection, optimization and intelligent selection of various grains such as rice, beans, nuts, grains, seeds, dehydrated vegetables and industrial plastics.

Meet the requirements of high-precision separation

The new multi-core parallel processing system can sort according to color, shape, texture, edge distribution, etc;

The intelligent scheme is flexibly matched and operated synchronously, and the operation speed is greatly improved;

Multi dimension, multi space, large-scale operation, fusion of Super Brain recognition, to achieve color selection adaptive operation.

New generation software, more user oriented

The full-color high-speed line scanning imaging CCD sensor for international cutting-edge industry, and the special lens for color selection made by international top suppliers, can accurately identify 0.04mm fine lesions and meet the high-end color selection requirements;

With high-resolution, high-sensitivity industrial image sensor and high reliability system design, it can instantly capture small defects and ensure the reliable operation of the equipment.

Anti crushing receiving device

Through feed structure, greatly improve the machine output;

The straight through discharge hopper structure solves the problems of material blocking and stacking, reduces material collision and effectively reduces material damage.

Multiple optical path technology -- realizing no dead angle sorting

The latest and original smart led formless cold light source, combined with the new multi angle invisible light path technology, makes the negative shape of materials disappear completely, so that there is no hiding place for small lesions and needle tip black spots, which makes it easier to identify, judge and sort more accurately;

Long service life, high luminous efficiency, strong anti-interference stability, startup without preheating.

Unique identification technology makes malignant sundries nowhere to hide

Unique identification technology can effectively remove malignant impurities such as glass, feces, stones, transparent plastics, etc.

New spray valve system

Larger output and higher removal efficiency;

The service life is up to 10billion times.

Technical parameters:

|

|

Product model |

CS1 |

CS3 |

CS5 |

CS7 |

CS8 |

CS10 |

CS12 |

|

|

Yield |

0.5-0.8 |

2-5 |

3-8 |

5-10 |

7-12 |

8-15 |

10-16 |

|

|

Number of channels |

64 |

192 |

320 |

448 |

512 |

640 |

768 |

|

|

supply voltage |

180-240V(50Hz) |

||||||

|

|

Overall power (kw) |

1 |

2 |

3 |

4 |

4.5 |

5 |

5.5 |

|

|

Air supply pressure |

0.6-0.8MPa |

||||||

|

|

Air source consumption (M ³/ min) |

<1.0 |

<3.0 |

<4.5 |

<6.0 |

<7.0 |

<8.5 |

<10 |

|

|

Dimension (mm) |

1058*1562*1897 |

1686*1562*1897 |

2314*1562*1897 |

2942*1562*1897 |

3256*1562*1897 |

3884*1562*1897 |

2628*3100 |

|

|

Machine weight (kg) |

200 |

400 |

700 |

800 |

1000 |

1200 |

1400 |

Color selection range